|

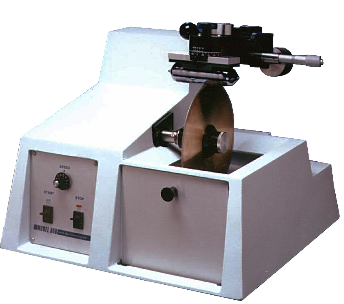

The Model 660 is designed to be a multipurpose precision saw using diamond wheels up to 7" in diameter. It's low speed allows it to cut all materials traditionally cut with a high speed diamond wheel while also cutting very fragile and soft materials with minimal subsurface damage.

A variety of sample holders provides a means to mount any shape sample while goniometer adaptability simplifies the cutting of orienting crystals.

|

Operation A sample is mounted to a sample holder and attached to the arm. An appropriate load is applied by adjusting the counterbalancing weight and the automatic stop switch is set. |

|

Cutting Wheels The Model 660 is designed to cut with diamond, CBN and abrasive wheels. Diamond wheels are used for most applications while CBN wheels are primarily used for cutting ferrous based materials. |

|

Features

|

|

Delivery including:

|

|

|

Click image to enlarge

|

Optional accessories |

|---|---|

|

Single Axis Goniometer |

|

Vise Holder |

|

Reservoir Adapter (for using 3" & 4" diamond wheels) |

| Right Angle Holder | |

| 2-Axis Goniometer | |

| X-Ray Track Mount (for 1.99" or 2.19" wide x-ray or optical tracks) | |

| The Model 250 2-Axis Goniometer (all stainless steel, includes mounting blocks and orientation software). It can also be adapted for use on all of our slicing and lapping equipment. | |

| X-Ray Track Mount for Model 250 (for 3.625" ht.) | |

| X-Ray Track Mount for Model 250 (for 4.0" ht.) | |

| 3-Axis Goniometer(includes 1" riser and fits directly on x-ray track) | |

|

660 work arm for Model 260 |

|

Ball Joint Holder |

| Petrographic Sample Holder |