- Sputtering, vaporising of carbon thread and plasma treatment (hydrophilic/hydrophobic) with one single device.

- Use of targets with a diameter of 54 mm and a thickness of up to 3 mm, which can be changed quickly and easily.

- Long live targets

- The magnetron sputter head allows for fine-grained sputtering for high-resolution FESEM applications.

- Sputtering of indium tin oxide (ITO) and carbon possible.

- Glass reaction cylinder Ø120mm (DIN 100 ISO-KF compatible) with implosion guard and safety monitoring.

- Automatic target shutter

- Electronically regulated process vacuum with Pirani and cold cathode measuring system

- Automatic valve control for two process gases and venting

- Target cooling with temperature monitoring

- Round stage, height-adjustable and tiltable (Ø80mm) to hold your samples. The table can be easily removed without tools for cleaning purposes (sandblasting).

- Speed-controlled rotary or planetary gear table with a range of options for holding samples

- Film-thickness measurement via double-quartz measuring system (for small samples at the centre, for large samples at the edge)

- Integrated ‘MD 1 Vario-SP’ membrane pump (HV version)

- Integrated ‘Hi Pace 80’ turbo pump (HV version)

- Wide-range power supply (90VAC to 260VAC)

- 5.7’’ TFT-Touch graphical display

- Intuitive user software with many useful features

- Easy creation of coating recipes, which guarantee reproducible results

- Storage/view of the last ten processes

- Graphical representation of process data with Windows-based software Coating LAB.

- Feature for automatically venting the system in the event of power loss. This prevents the system from getting contaminated by backing pump oil (LV version).

- USB interface for easy process analysis and software update

- Uniform interface for different process heads

- Automatic process head recognition

- 6mm Legris connections for two process gases and a venting gas

- Flange connection (DN 25 ISO-KF) for connecting an external backing pump (LV version)

- Can be used as a pure pumping unit

- Small size and low weight

- Swiss quality

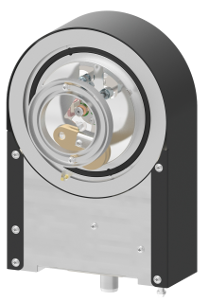

SP-010 SPUTTERING MODULEThe SP-010 sputtering module for the CCU-010 LV and CCU-010 HV Compact Coating Units has a small form factor, yet offers all the features required for highquality sputter coating in a vacuum. Highlights

|

|

CT-010 CARBON THREAD MODULE

|

|

RS-010 ROTARY STAGE

PLANETARY STAGE PS-010

An integrated plug connection for the motor and layer thickness sensor allows the sample table to be exchanged in seconds.

Universal, smooth adjustment of table height, tilt angle and rotational speed guarantee exceptionally homogenous films even on very jagged samples.

Samples can be arranged optimally on the table thanks to the intelligent layout of mounting holes for SEM stubs.

Compact pancake design enables handy preparation and sample transport with a height of just 23 mm with an 80 mm diameter.

COATING-LAB

This Windows-based software is easy to install on your laptop and offers diverse options for monitoring and documenting processes.

Fully automatic logs with selectable charts containing all process-related data can be exported as screenshots or CSV files for your Office applications.

Other outstanding features include parameter management, intuitive software upgrades and where-used lists for the system.

Highlights

- Auto-connect functionality automatically connects the laptop and coating unit via a USB interface.

- The last 10 processes executed by the unit are stored and depicted in the history function.

- The pressure, current and voltage for the process are displayed along with the film thickness and coating rate.

- An extensive parameter database enables users to tailor the system to fit the application environment like a glove.

- With an Internet connection, Coating-LAB can easily establish remote access for error diagnosis and process optimisation.